Research Center

Integrated Precision Technology Research Institute

Connecting the flow of technology into one.

We possess an integrated research and development system capable of independently carrying out the entire process, from design, analysis, testing, and evaluation to manufacturing. By analyzing and verifying the performance and reliability of high-precision components, we achieve the highest level of product quality.

Based on accumulated know-how and proven technological expertise, we are able to provide immediate and flexible technical responses to meet the diverse requirements of our customers. Going beyond simple processing, we design the future with precision solutions completed through technology.

Research Process

-

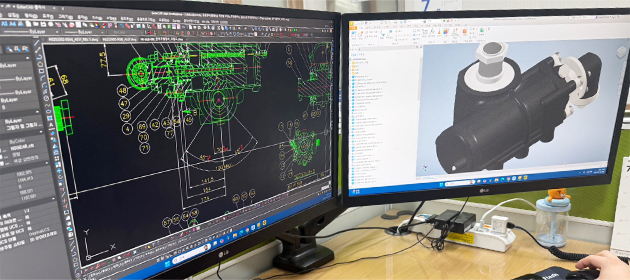

01Design

- Size compact design based on individual parts and system configurations

- Optimal customization design according to user requirements

- Shape design considering interface optimization

- Environmental condition design based on MIL-STD standards for defense, aerospace, etc.

- Localization optimization design for imported reducers and gears

-

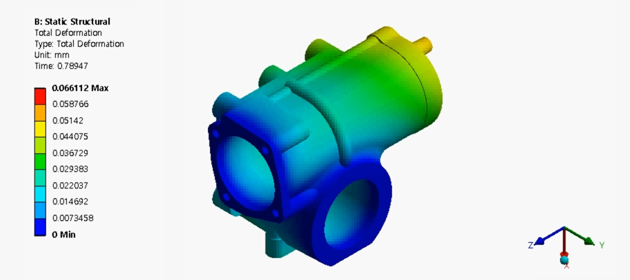

02Analysis

- 3D modeling and interface verification

- Reliability analysis including structural, vibration, and flow analysis

- Bearing life prediction, geartrain dynamic analysis

-

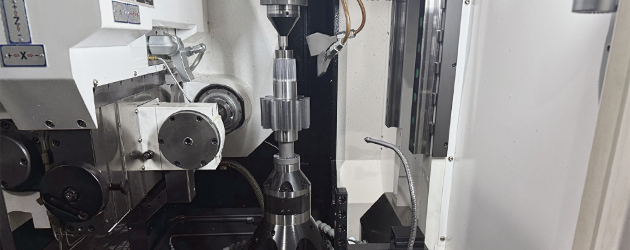

03Production

- High-precision machining equipment and ultra-precision assembly technology

- Design and application of precision, low-noise, low-backlash geartrains

- Production of high-efficiency, high-load, high-rigidity, and high-durability gearboxes

-

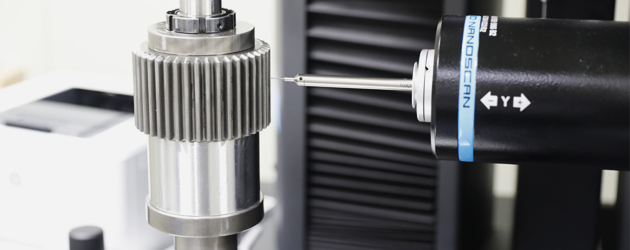

04Test Evaluation

- Performance testing of individual parts and assemblies

- No-load/load/temperature tests and in-house durability testing

- Environmental testing (MIL-STD standards): vibration, shock, temperature, humidity, etc.

- Collaboration with external accredited testing organizations